Last updated 21 April 2020.

We are updating the church’s air conditioning system, which has served us well for over 60 years. This is a large project, costing over $200,000. Most of the work is complete, and we have just received an invoice covering the portion just completed for over $100,000. If you would like to contribute to this project, please note “Air Conditioning Fund” on your check. Or click the Donate button below to donate online. Your support will be much appreciated.

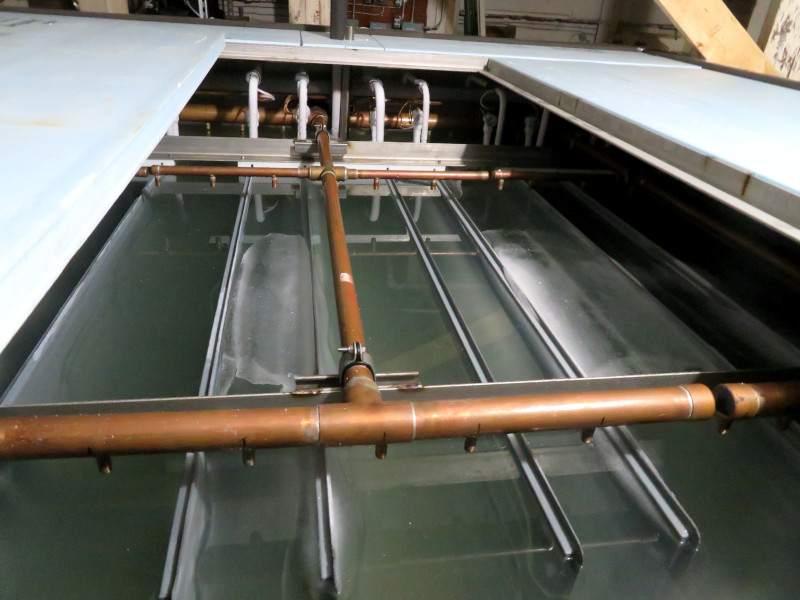

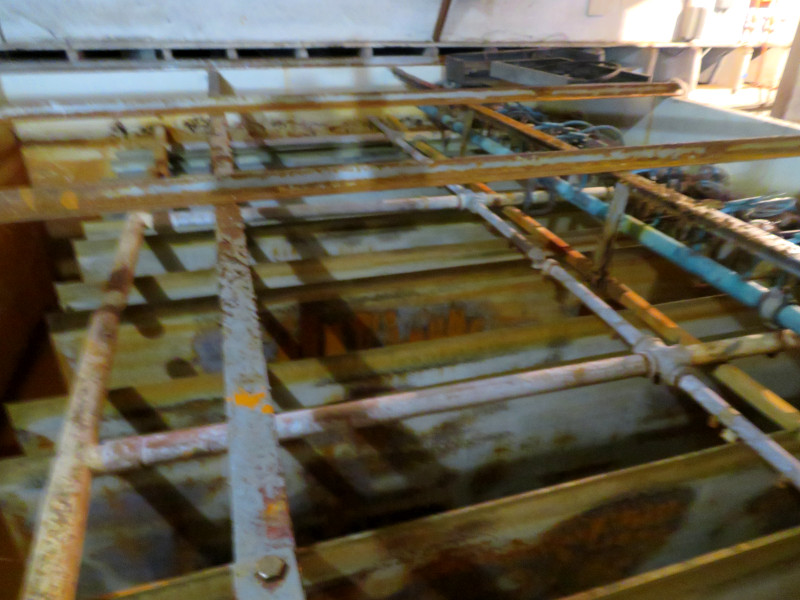

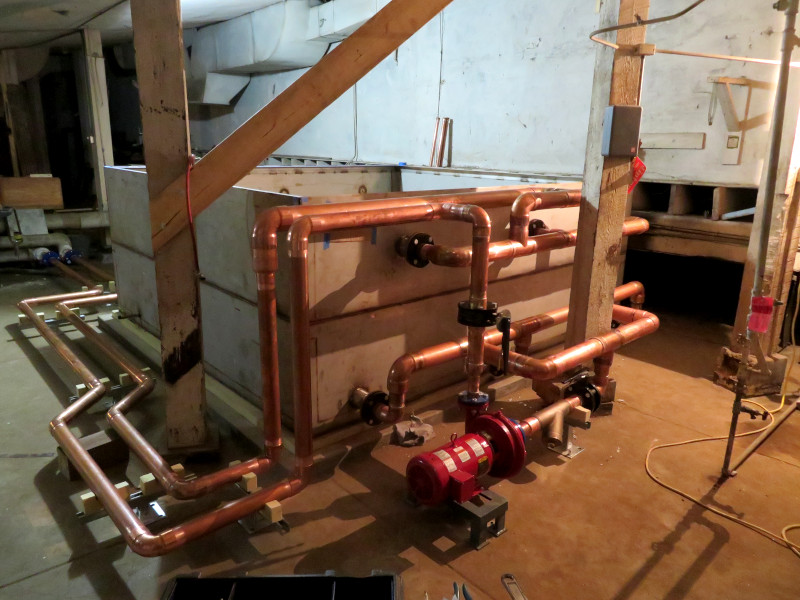

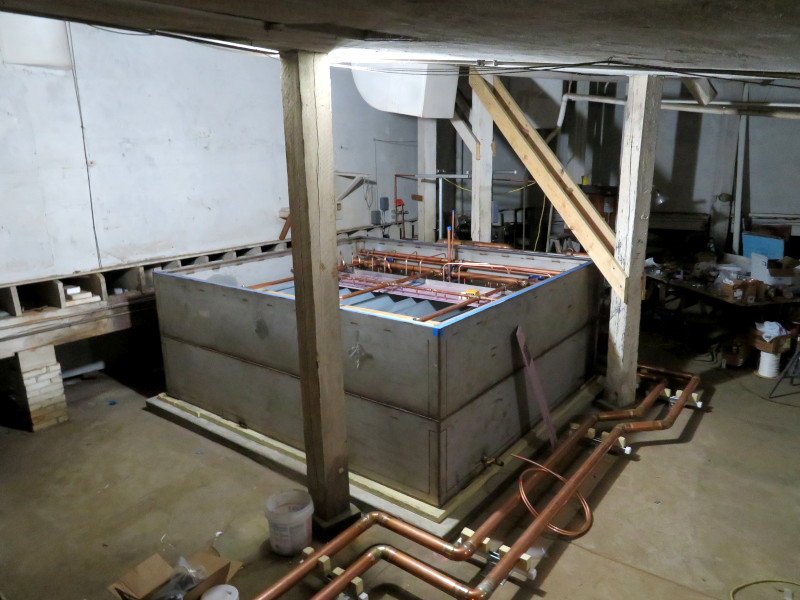

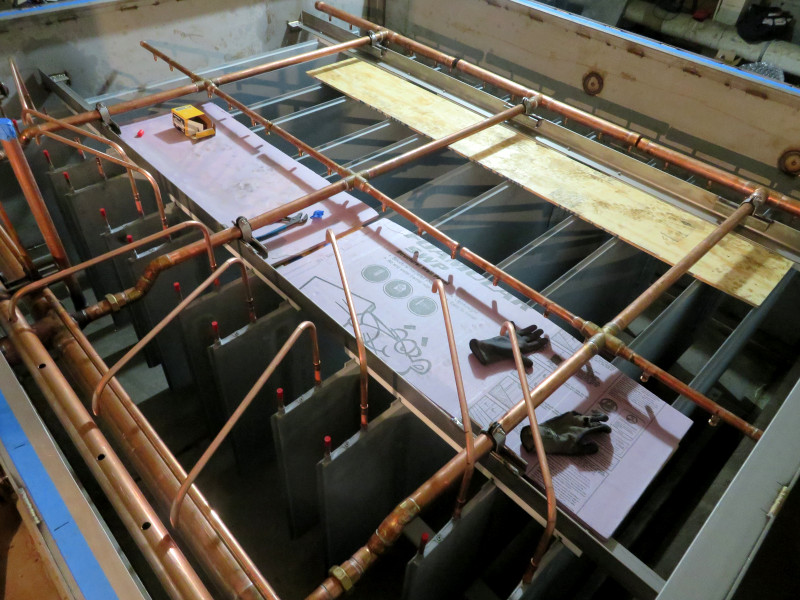

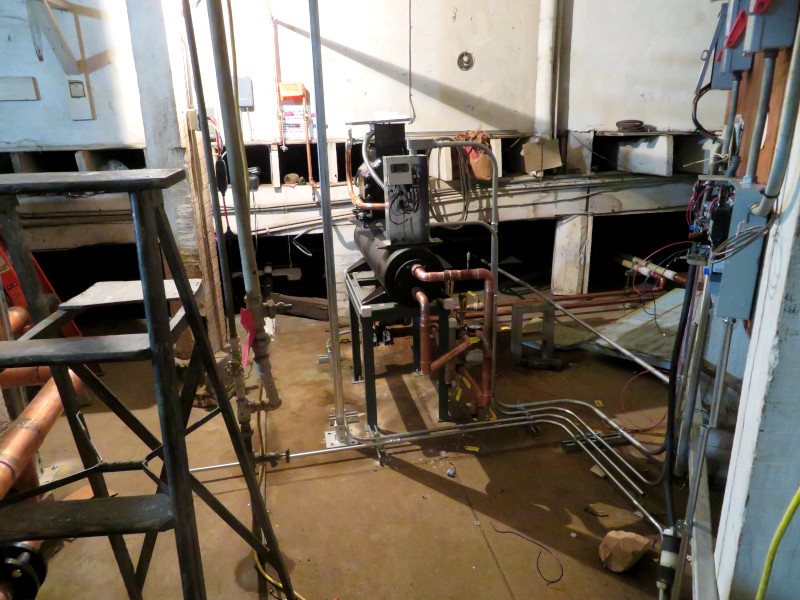

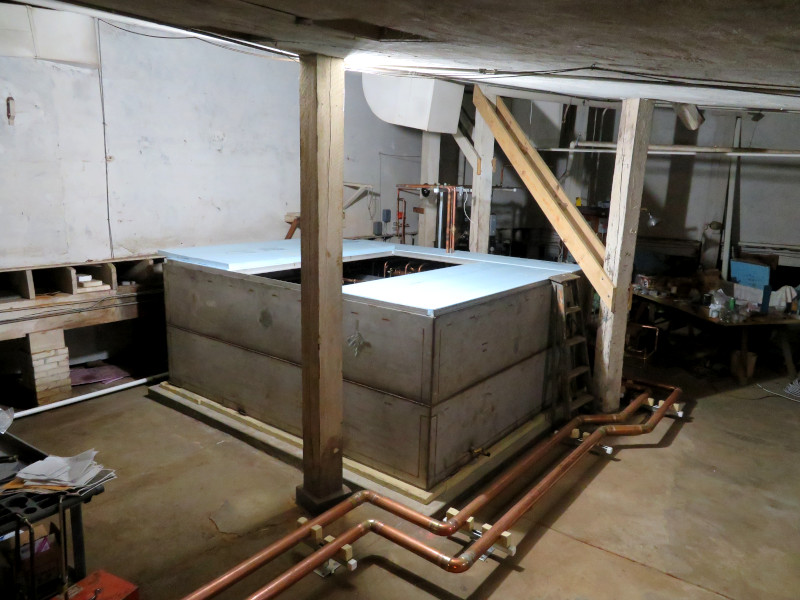

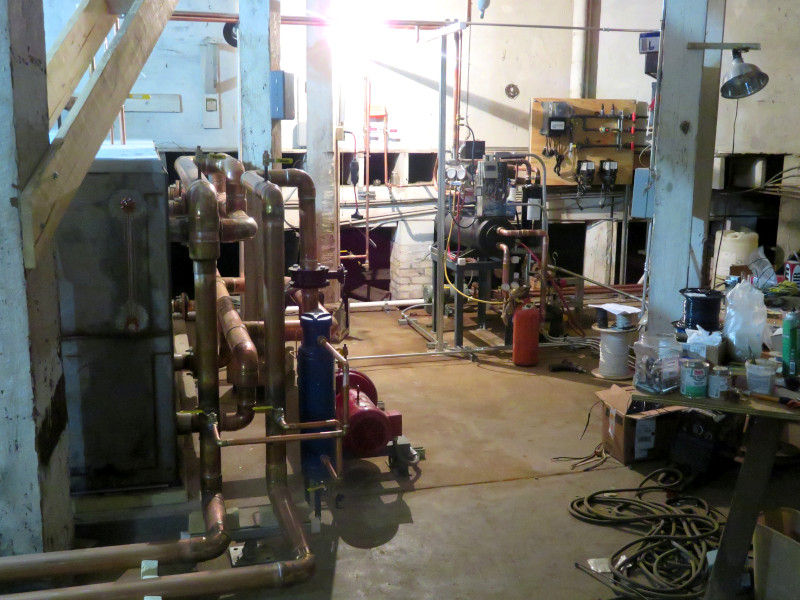

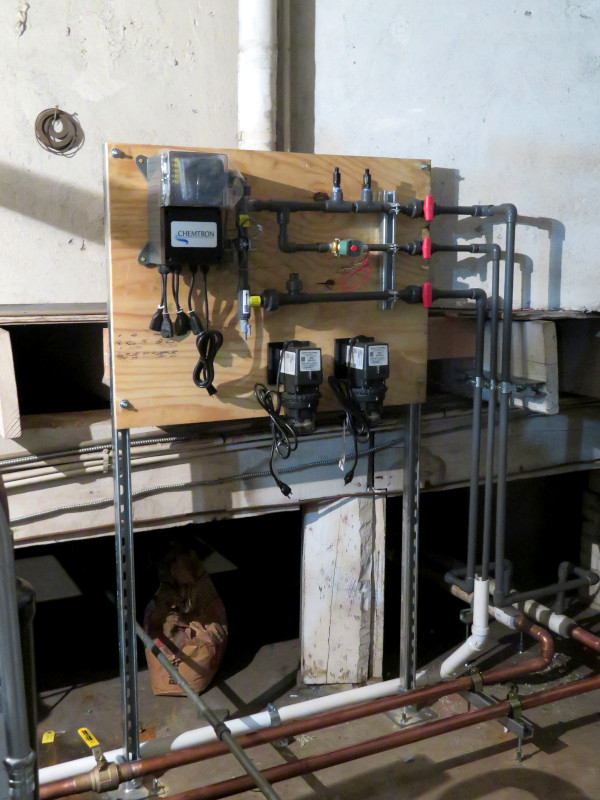

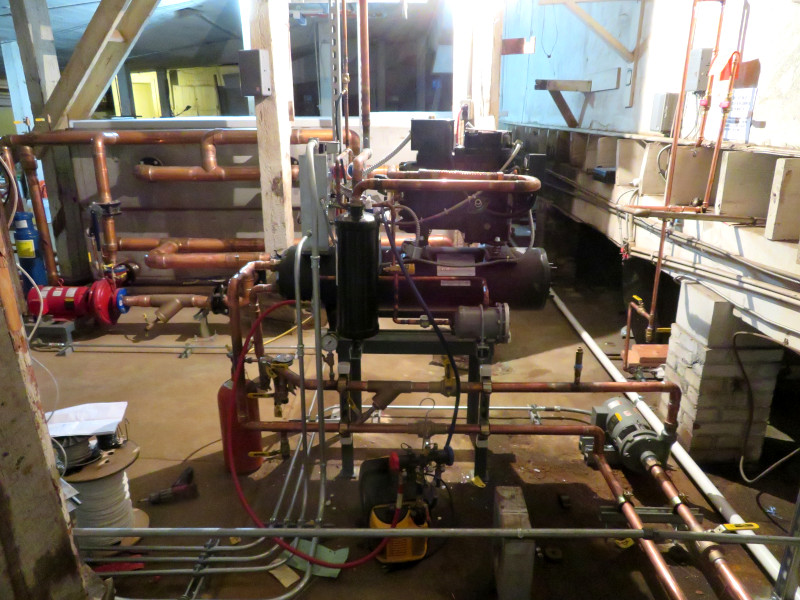

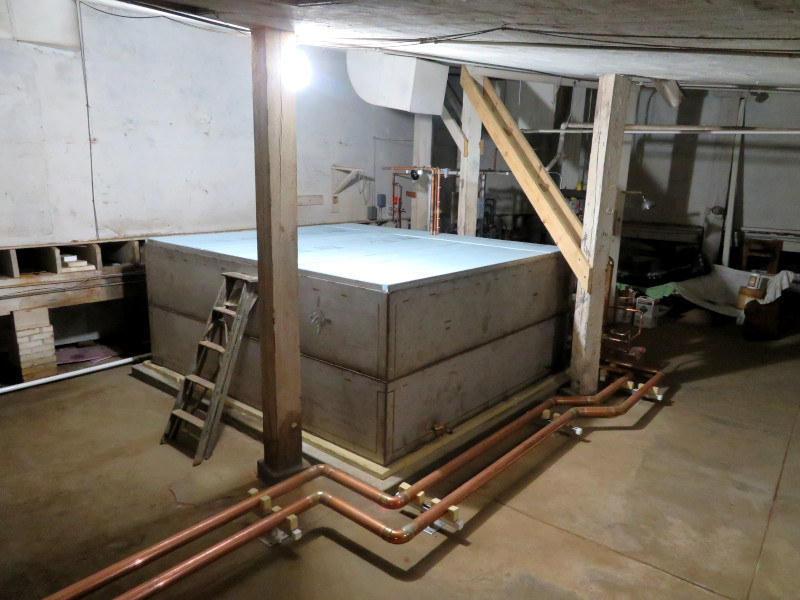

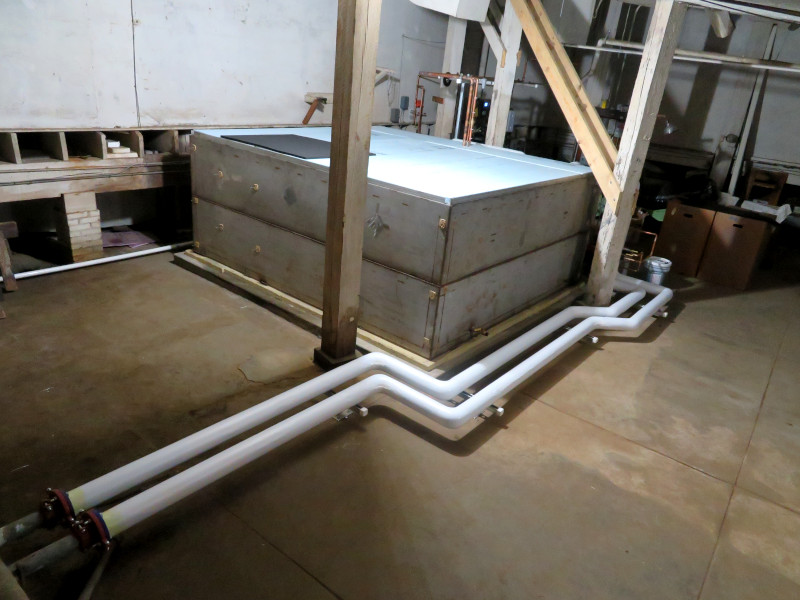

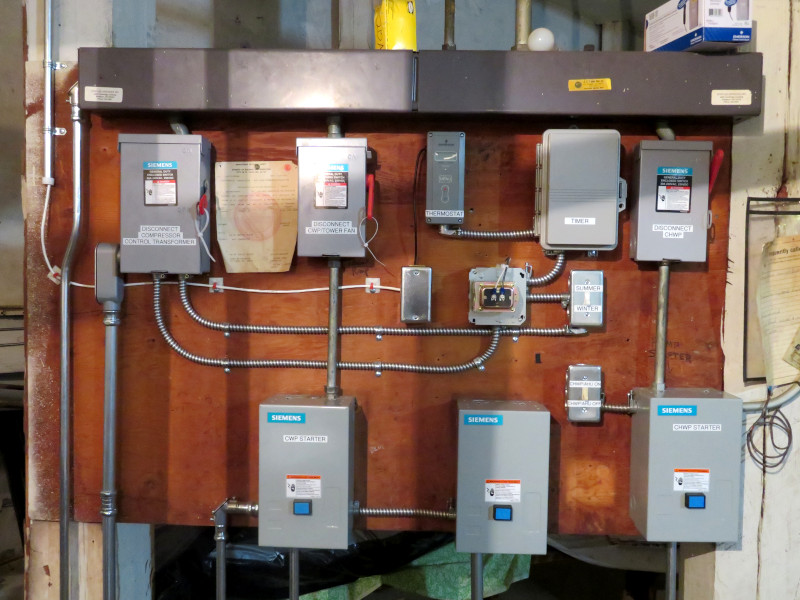

The following photos show the progress that has been made so far. We hope you all will continue to support this project.

Apr. 24, 2020: The Albert Arno project manager reports that the system is now operating and making ice. They will continue testing the following week.